铭发 miefar intelligence

-

Home

- About Us

- Products

- Case

- News

- Online message

- Cooperation

Classify- MGR-H breathing tumbling machine

- MGR-T tilting vacuum tumbling machine

MGR-T tilting vacuum tumbling machine

ProductsContact us

Contact person: Mr Wang

Tel: 136-0895-3113

邮箱:13608953113@163.com

Address: Tuqiang Industrial Park, Zhucheng City, Shandong Province

MGR-T tilting vacuum rolling machine

Scope of Application

The MGR-T series rolling and kneading machine adopts a swinging bracket and horizontal inclined rolling and kneading. Compared to MGR-H series models, it has greater loading capacity and more convenient unloading performance. Suitable for pickling and processing Western style sausages, ham, bacon, grilled meat, as well as traditional Chinese poultry, sauce braised, and snack foods.

There are also refrigeration jacket models available.Technology and Applications

1. It has continuous vacuum function. There are two working conditions to choose from: vacuum rolling (fixed vacuum degree) and breathing rolling (alternating vacuum and atmospheric pressure); Equipped with a vacuum gauge to display the vacuum level of the rolling barrel in real-time. The use of breathing kneading function can effectively shorten kneading time and improve kneading efficiency. The vacuum gauge is convenient for monitoring the vacuum condition at any time.

2. Adopting variable frequency stepless speed regulation, with a speed range of 2-12rpm (1-4 rpm low-speed function can be selected), the optimal processing technology can be selected to improve production efficiency; Save energy consumption; Start smoothly, reduce the impact during machine startup, and extend the service life of the equipment.

Choose the low-speed function to adapt to various rolling and deformation prone products, especially poultry and fish products.3. Comprehensive feeding and unloading solutions. The swinging rolling bucket bracket tilts the bucket forward, allowing for thorough unloading.

Vacuum suction or integrated feeding mechanism can be selected for loading according to different product characteristics. Specially configured auxiliary material vacuum suction tube.4. Adopt PLC and touch screen control.

Long term validation of highly reliable control systems, with more intuitive touch screen operation and excellent water and moisture resistance.

You can choose the traditional rolling mode, the forward rolling one pause one reverse rolling one pause cycle mode, or the personalized rolling mode. The total working time can be divided into up to six process steps, each process step is divided into two sections, and each section is separately set with time, speed, vacuum state, and direction. Meet the processing requirements of diverse products.5. High standard hygiene design.

The whole machine is made of high-quality SUS304 stainless steel material;

The interior of the drum is finely polished, with no hygiene blind spots, and the discharge position can be completely drained.6. Adopting a water ring vacuum pump, equipped with a vacuum pipeline filter, and selecting high-quality vacuum sensors to improve the reliability of the vacuum system.

7. Optional“ V-shaped” And“ Single piece type; Paddles, with different rolling and kneading forces, adapt to different products.

8. Adopting a reducer direct drive, the operating noise is lower and the efficiency is higher.

Accessory selection function

1. Feeding mechanism

It can be equipped with a feeding mechanism that is integrated with the machine for loading, suitable for materials such as poultry, aquatic products, and large meat that are not suitable for vacuum suction.

MRC-500 suction truck

Capacity 500L, movable, connected through vacuum tube and rolling drum. It can accelerate the feeding efficiency, especially effective for larger meat pieces or meat fillings with low water content.

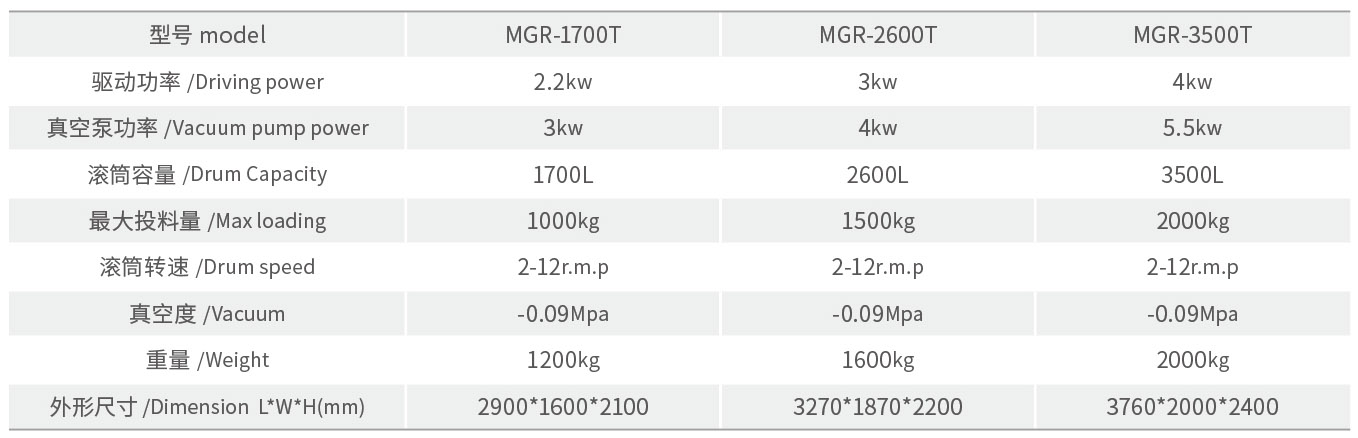

parameter table

- Previous:It's already the first one

- Next:It's the last one

相关产品

More>>

© Shandong Miefar Intelligent Equipment Co., LTD All Rights Reserved. 鲁ICP备8888888号

Mobile terminalWechat Public Platform-

Contact person Contact Us

Manager Wang

-

Contact number Contact Us

-

E-mail Email

-

Address Address

Tuqiang Industrial Park, Zhucheng City, Shandong Province

- About Us